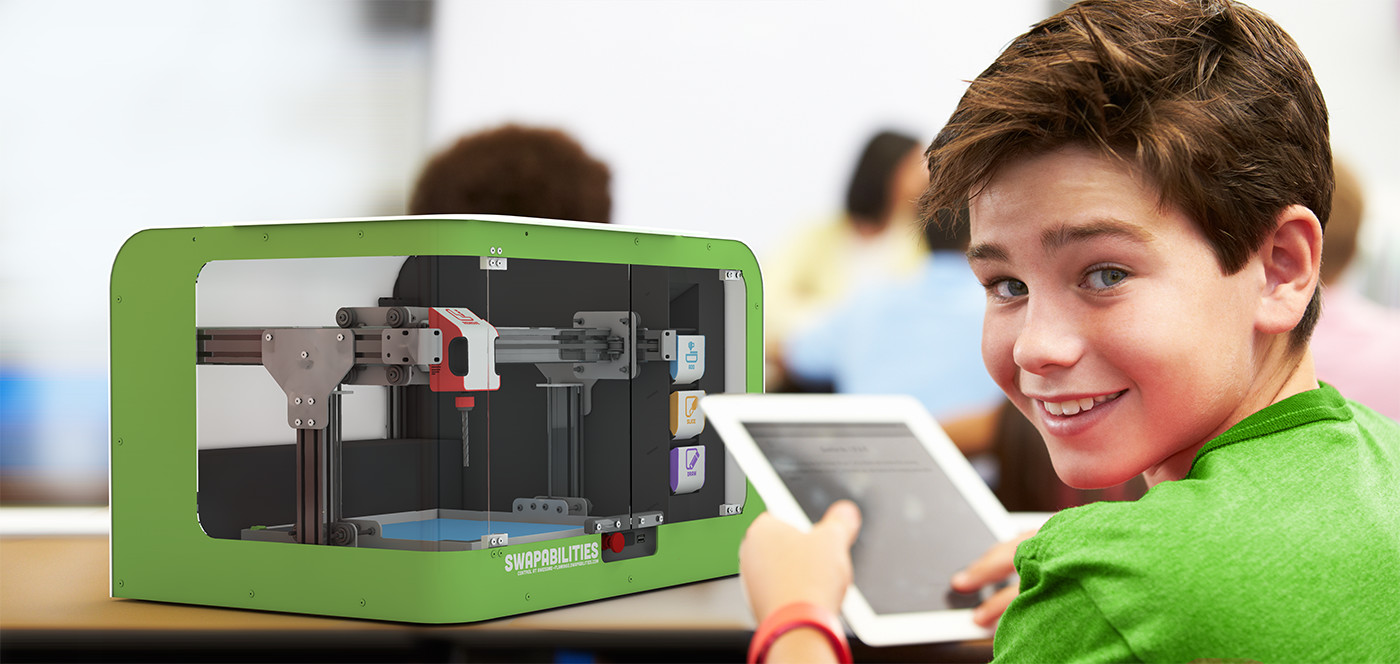

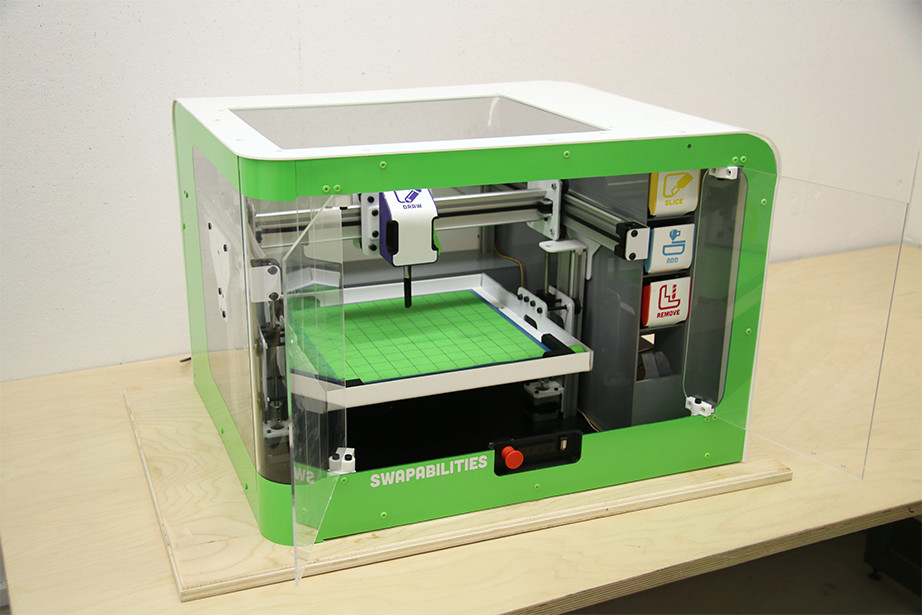

I designed Swapabilities, a 4-in-one rapid prototyping tool that provides turnkey access to 3D printing, CNC machining, 2D cutting and plotting in a simple compact package for education and learning.

Educators are increasingly aware of the potential of making and design in increasing student engagement, particularly among otherwise hard-to-teach students. Rapid prototyping technologies combine art with science, and potentially allowing students to create anything they can imagine without having to learn their way around a workshop.

However, adoption has been slow so far. Through interviews with educators, I identified three main obstacles to adoption:

Project Details:

Skills

- Requirements Gathering

- Prototyping

- Industrial Design

Organization

- Carleton University

Date

- September 2013-April 2014

Logistics

Many rapid prototyping technologies means many tools, each of which takes up room in a classroom or workshop and presents it's own training barrier.

Safety

Many rapid prototyping technologies have parts that could seriously burn, cut or crush a student, while curious students can easily damage fragile technology.

Support

It's not enough just to own the machines - Even more equipment, such supplies for clamping, maintenance and lubrication may be required!

Swapabilities using a swappable tool head system to combine the functions of many different processes into a single machine!

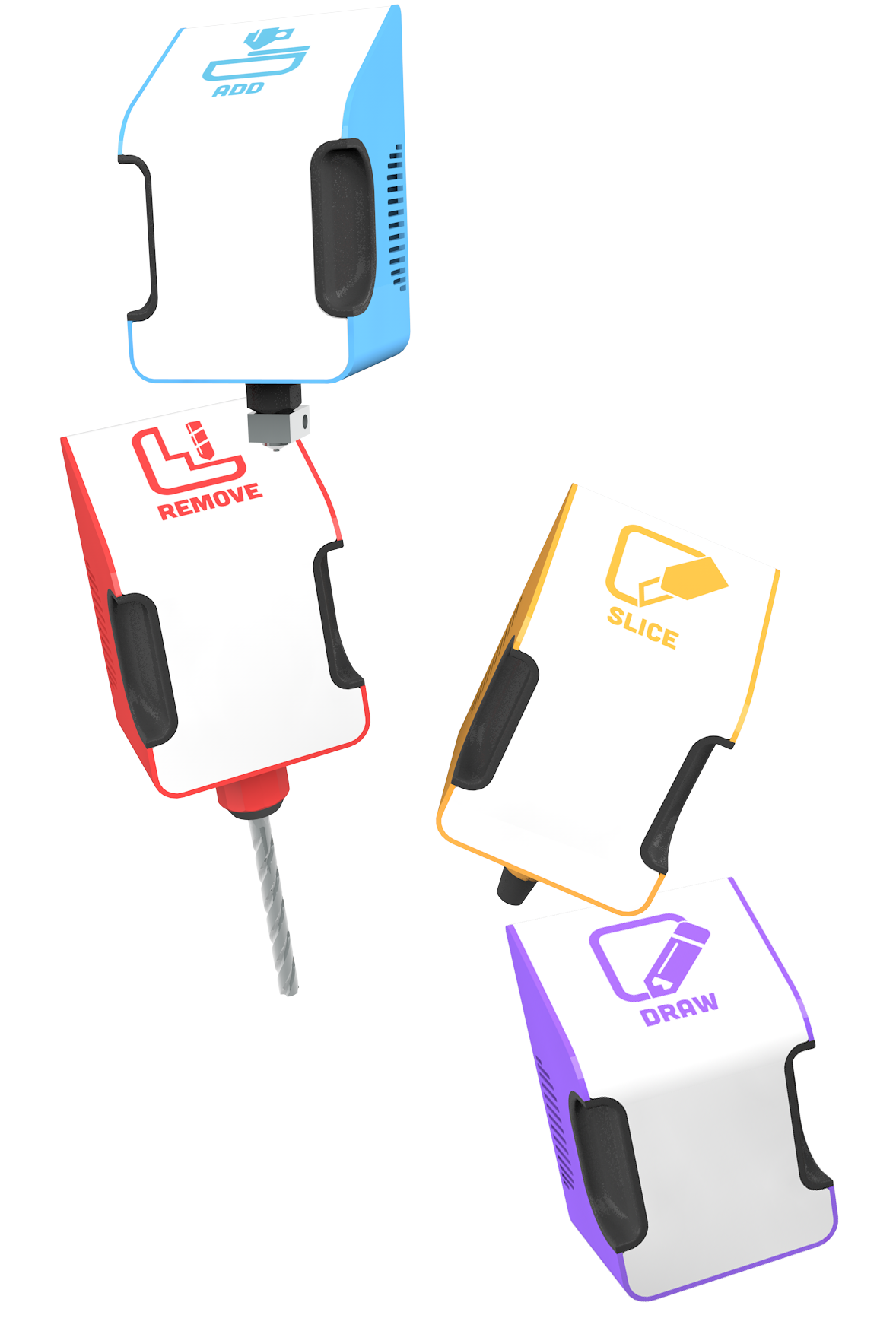

The Add Tool turns Swappabilities into a 3D printer, building up parts layer by layer from melted plastic and to create detailed and strong parts - custom wheels for a small car, or gears to learn about motion.

The Remove Tool carves away material in three dimensions, allowing students to craft parts from common light materials like foam and soft woods. Useful for art projects and larger parts.

The Slice Tool uses a small knife to cut thin materials like paper or fabric. A fast method that makes it easy for students to get started with using their own designs.

The Draw Tool allows students to experiment, and clip in anything they want to move: pens, chalk and more.

These tool heads can be swapped with a simple lever. Electrical contacts in the base give power to the tool - this means that if a tool ever comes loose, it powers down automatically!

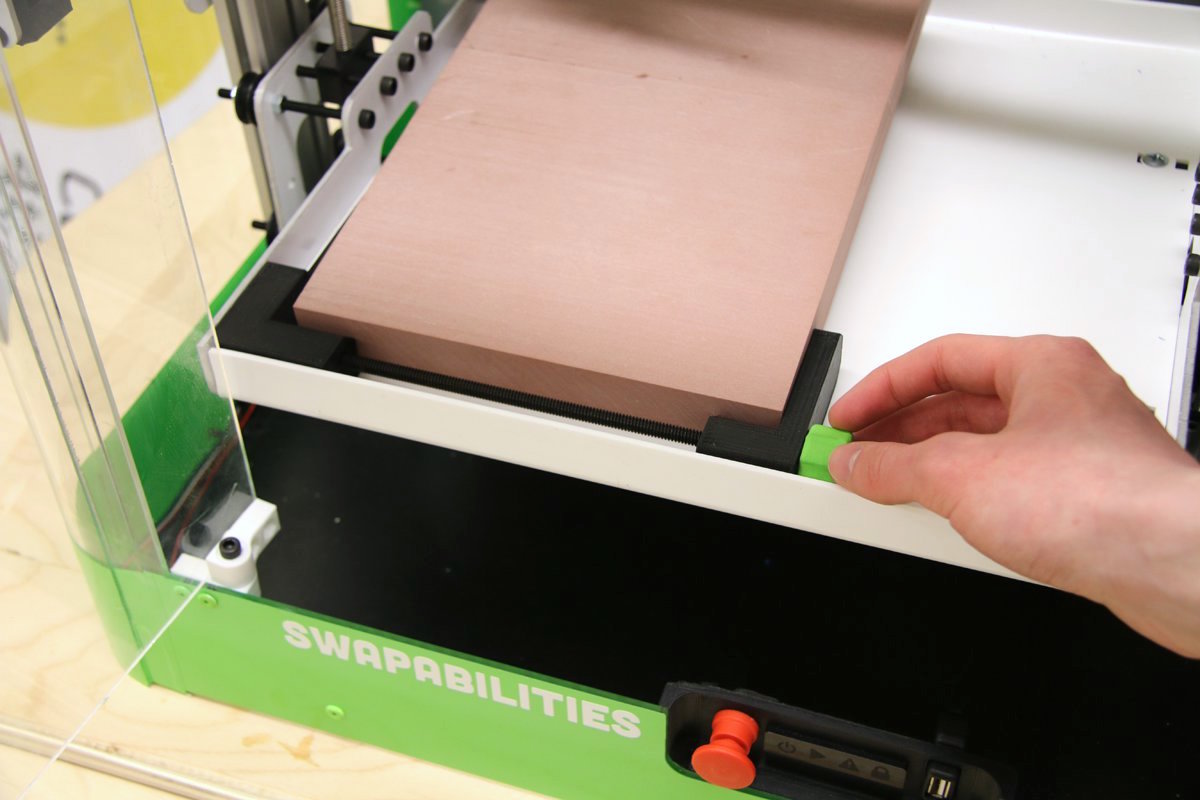

Quick-adjust clamps in the bed of the machine allow for material for the remove tool to be easily secured. Slide the nut into place, and give a half turn to lock.

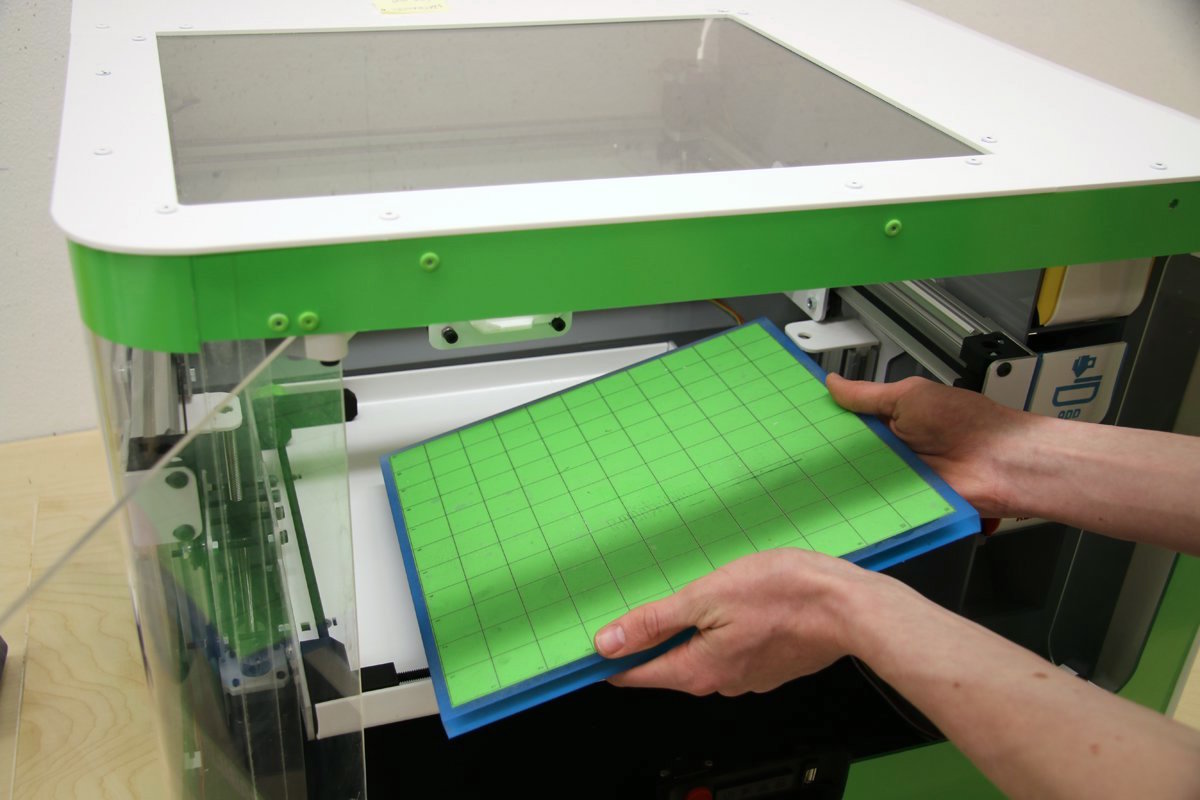

The same clamps are used to secure the surface used for printing and slicing. One side is lightly textured to allow for the Add Tool's prints to stick, while the other side has a resettable adhesive to secure paper or fabrics for the Slice or Draw tools.

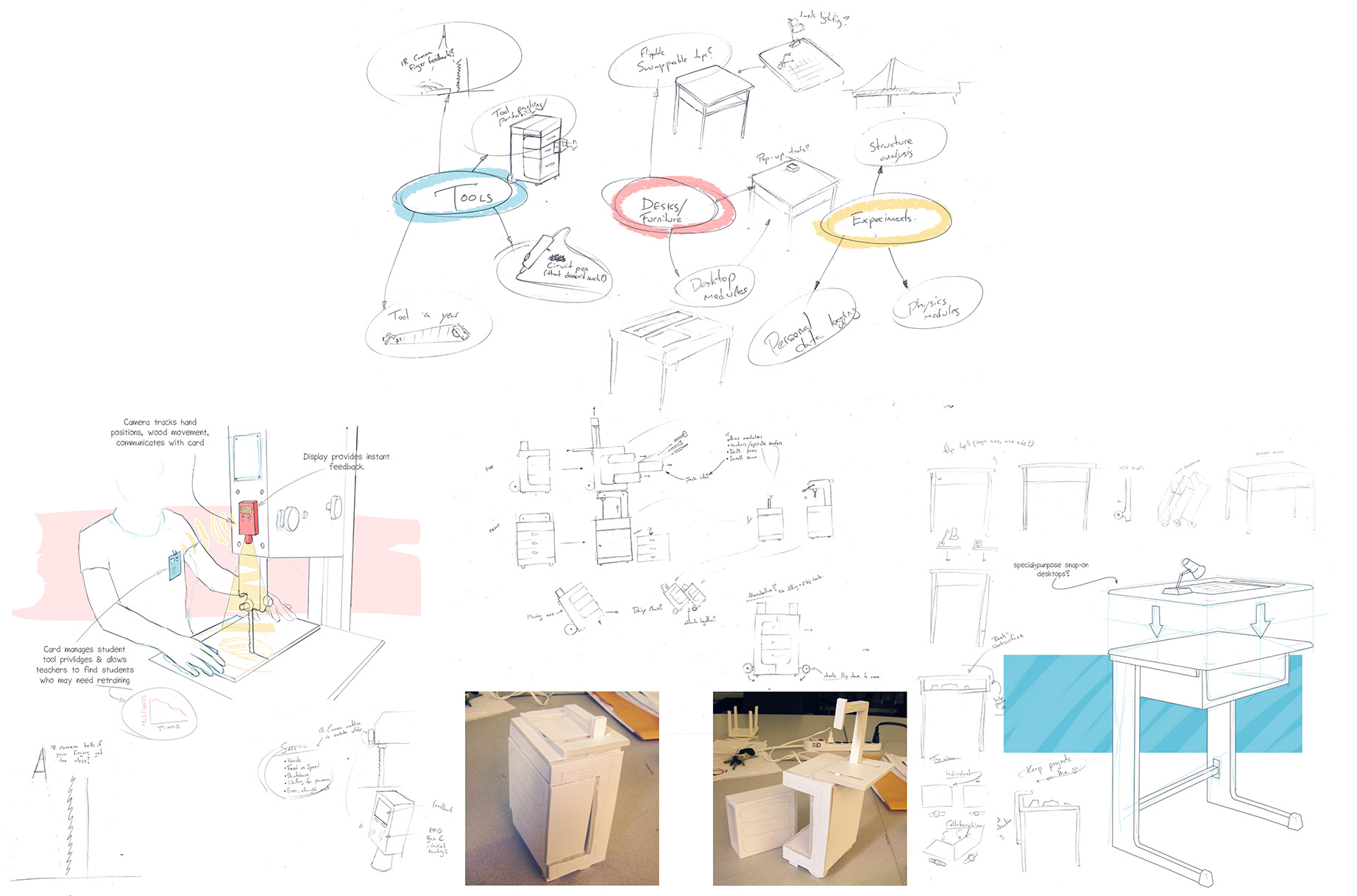

Process: Ideate

The path to the Swapabilities concept was not a smooth one. Early design efforts focused on ways of bringing more traditional workshop tools into the classroom or integrating new technologies into science experiments. One concept I spent some time on revolved around the idea of "tool carts", that would act as portable self-contained workshops. However, I eventually realized that traditional tools had too many complications for a classroom context. Instead, I decided to focus on a multi-function self contained rapid prototyping device.

After a bit more iteration to refine details, this concept proved popular with educators so I began prototyping.

Process: Prototype

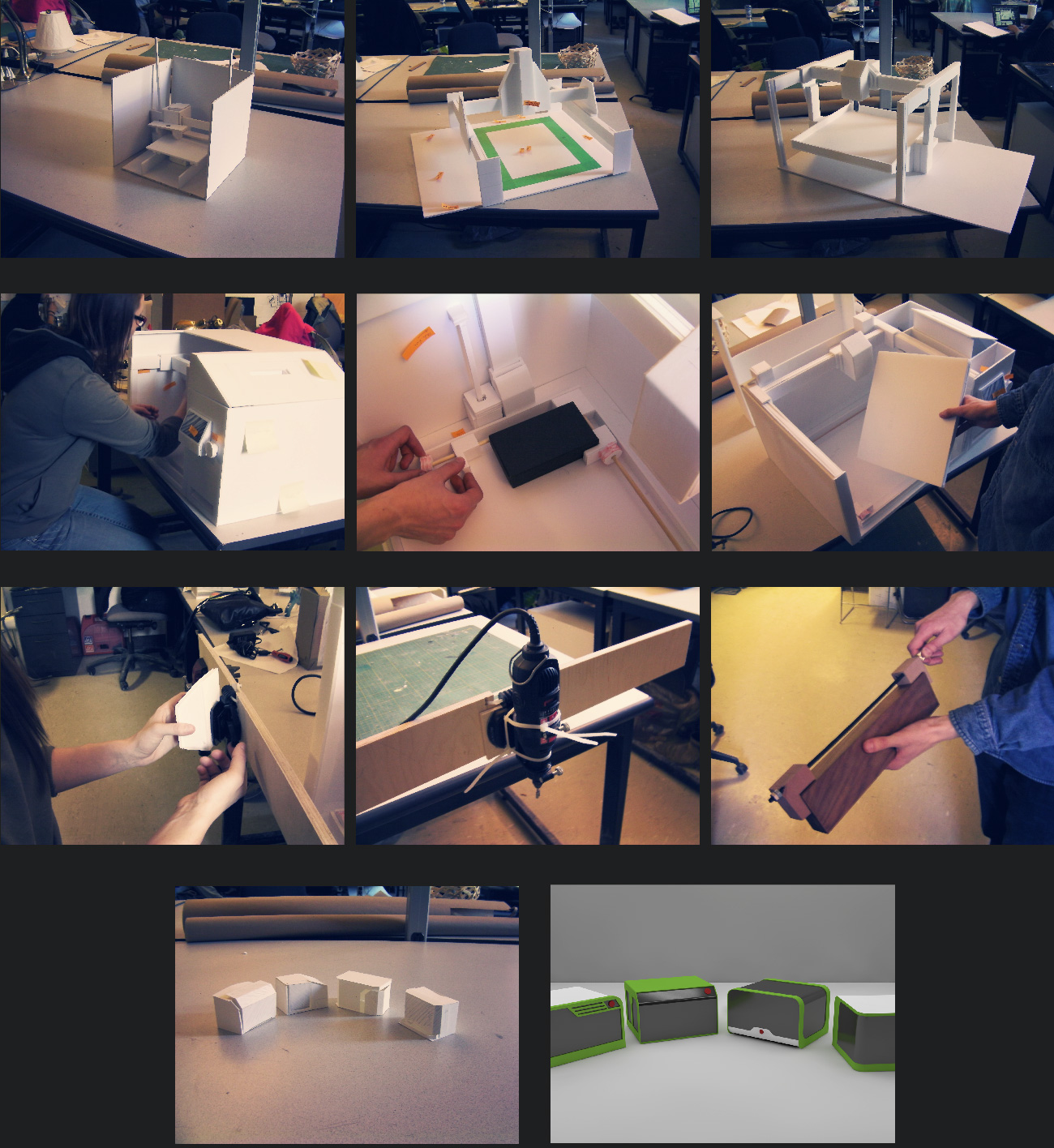

Overall form prototypes: Since fitting everything into a compact package was a major concern, I built many iterations of partial and full-scale foamcore models to get a better understanding of how everything would fit together.

Feasibility prototype: Many of the interior mechanisms, such as the tool-less clamping system and the head swap mechanism were functionally prototyped using 3D printed or off-the-shelf elements. These prototypes, and the full-scale foamcore prototypes were hallway tested for ergonomics.

Aesthetic prototypes: I prototyped the aesthetics of the exterior using foamcore, paper and fast CAD models.

Process: Build

As Swapabilities was explicitly designed to be easy to build at low scales, For my final model I constructed a semi-working prototype. The final model featured working linear motion and tool swapping, and could draw business cards using the Draw Tool head.

Outcomes

I presented the Swapabilities final prototype to the educators I had been working with throughout the project, who were all very pleased with the design. I also presented the design to my regional representatives from the Industrial Designers Society of America, who selected my project for the regional Student Merit Award, and had me travel to New York to present my design at the 2014 IDSA Northeast District Design Conference!